No One Fabric Fits All

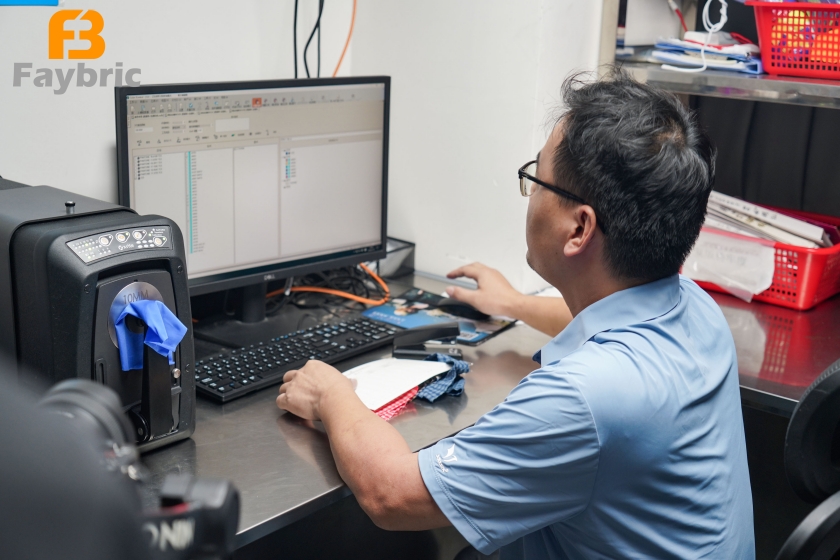

So Faybric is always creating, innovating and changing

Different scenarios:

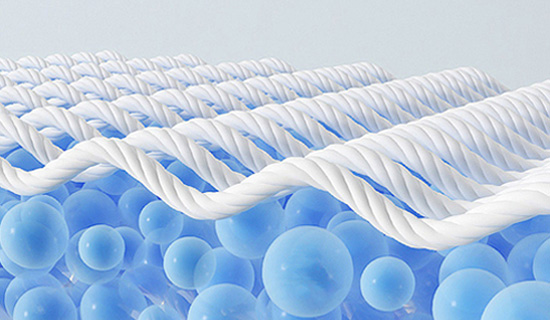

Nowadays, people have been making progress, and the use scenarios of functional fabrics are increasing. The importance of functional fabrics in various fields for different scenarios is constantly increasing. Users are increasingly concerned about the comfort, safety and practicality of fabrics. Faybric has been innovating and providing more comprehensive and high-quality fabric solutions for global customers in different fields.

Times change demands:

the progress of the times has led to changes in the fabric field through technological innovation, environmental awareness, personalized design, comfort improvement and other aspects. Faybric actively responds to the changes of the times and the diverse needs of consumers, and actively participates in material planning and environmental planning to make our products and services reach higher standards recognized by global customers.

More and more challenges:

With the development of the times, no one fabric is suitable for all situations, and we still face many challenges. Faybric is a responsible stretch fabric solution provider, insisting on product research and development as the core, building a full-link management of product development led by international fashion trends, and constantly creating, innovating and changing to provide customers with efficient value-added and sustainable fashion solutions.